Tel:0577-21019000

E-mail:zograjd@163.com

|

Environmental Temperature |

-30°C~+60°C |

Relative Humidity |

Not greater than 85% |

|

Working voltage |

AC 220V |

Contact Capacity |

220V AC 500mA |

|

Speed Range |

20~999r/min |

Switch form |

Normally closed (or normally open) |

|

Gear Specifications |

Φ120 / Φ150 |

reliability |

>106 |

|

Protection level |

IP65 |

Reference Weight |

3.5KG |

product manual:

This speed detector is a new type of device for detecting the belt speed of the conveyor. It detects the belt speed in real time and has been widely used in the belt of the conveyor system, which provides a reliable detection method for the safe operation of the belt conveyor. It needs to be horizontally installed on the conveyor bracket between the upstream tape and the downstream tape, so that the touch wheel and the surface of the tape have a certain pressure to prevent the malfunction of the wheel jump. When the touch wheel is driven by the belt conveyor to drive the inner pulse disk, the magnetic signal of the sensor is input to the control circuit when the pulse disk is rotated, amplified, and then counted. The count value is compared with the preset number to determine the belt speed of the tape, that is, normal speed, slip or overspeed, and the like. At the same time, the execution circuit outputs the corresponding switching signal.

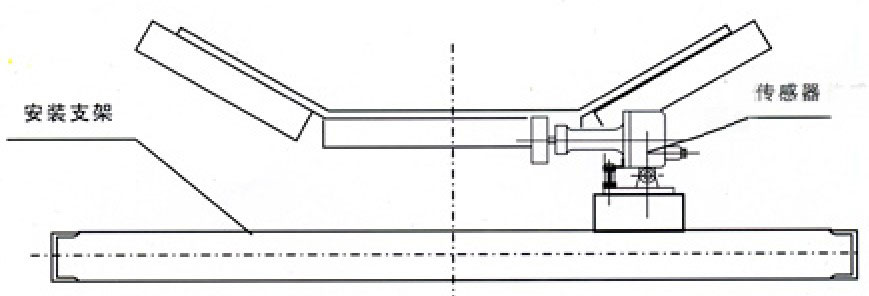

Structure:

1. This machine is composed of a touch wheel, a pulse disk, an electronic pulse switch, a housing, etc.

The contact wheel is made of cast iron, and the surface milling groove has wear-resistant sliding effect.

The shell is made of aluminum and the joint is equipped with a sealing ring to effectively reduce the weight of the body for better waterproof performance;

2. The switch inside the machine adopts the normally closed type. If the belt speed is lower than 80% of the normal speed, it can trip or stop.

physical dimension:

安装示意图: