Tel:0577-21019000

E-mail:zograjd@163.com

|

Environmental Temperature |

-30°C~+75°C |

Relative Humidity |

Not greater than 85% |

|

Working voltage |

AC 220V |

Contact Capacity |

24~380V AC/DC Current: 1:5A |

|

Action Itinerary |

10mm |

Extreme Itinerary |

20mm |

|

Action |

10KG |

reliability |

>106 |

|

Protection level |

IP65 |

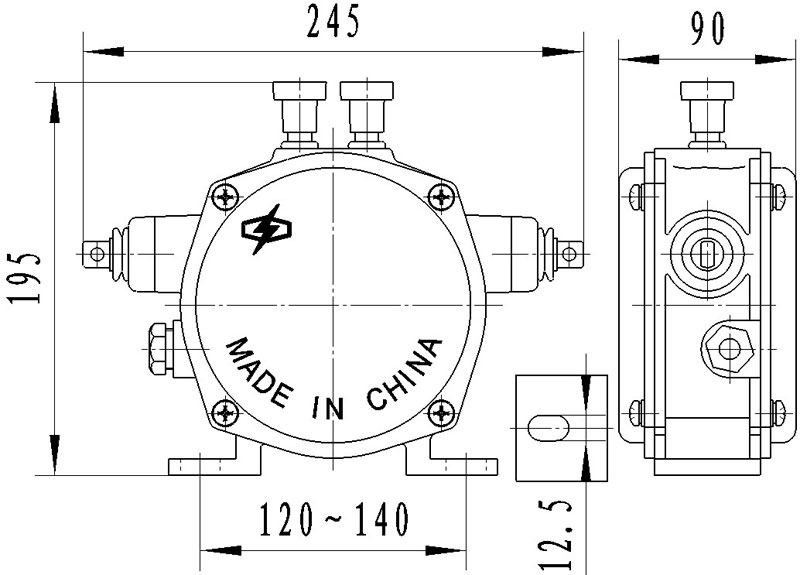

Reference Weight |

2.5KG |

product manual:

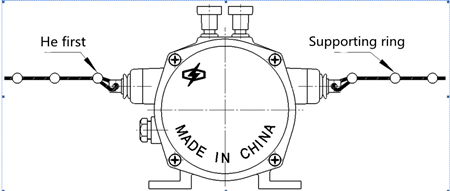

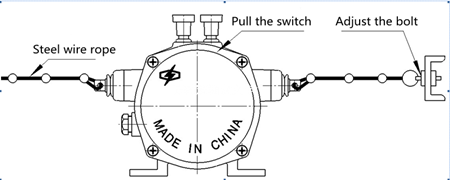

When an emergency occurs at the tape transport site, the wire rope attached to the lifting lug of the rope switch can be pulled, so that the slider inside the machine controls the internal micro switch to emit a shutdown or alarm signal. The automatic reset model is automatically reset after the wire rope is sent. The manual reset model needs to be reset after operating the reset handle.

The switch adopts aluminum alloy precision die-casting shell, which has high strength and light weight. The outer casing protection grade is IP65, which can work in harsh environment for a long time. The machine adopts high-quality stroke switch, large contact capacity, sensitive and reliable action.

Installation and use:

☆The switch is mounted on the rack fixing bracket in a balanced manner;

☆ Attach the wire rope to the pull tabs on both ends, each side rope does not exceed 30M

(When there is a slope, it should be shortened);

☆The rope tension should be suitable to ensure reliable reset of the switch;

☆ Pull the rope along the parallel direction of the tape, add a ring for every 10M;

☆The wire rope can be purchased by the manufacturer according to the specifications required by the user.