Tel:0577-21019000

E-mail:zograjd@163.com

|

Environmental Temperature |

-30°C~+75°C |

Relative Humidity |

Not greater than 85% |

|

Number of contacts |

1Normally open 1 normally closed (can be formulated) |

Contact Capacity |

24~380V AC/DC Current: 1:5A |

|

Action Angle |

30° |

Limited Angles |

60° |

|

Action |

10KG |

reliability |

>106 |

|

Protection level |

IP65 |

Reference Weight |

1.5KG |

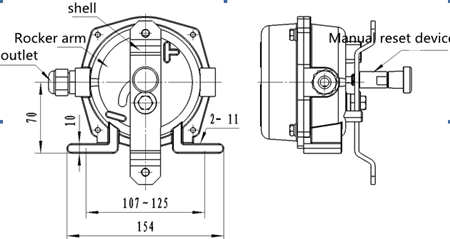

product manual:

The two-way rope switch is widely used in factories and mines with belt conveyors such as steel, cement, power plants and mines. The product is installed on both sides of the belt conveyor and is a kind of protection switch for the emergency stop of the belt conveyor. Pull the wire rope at any point within the operating distance, cut off the running circuit to stop the whole line, and realize the protection of the tape machine and personal safety. When an emergency occurs at the tape transportation site, the wire rope attached to the lifting ear is pulled to make the slider and the switch in the machine act to send a shutdown signal.

The product has long service life; good sealing performance, dustproof, shockproof and anticorrosive; the casing is cast by cast aluminum, which is light in weight and strong in hardness. Due to the lack of understanding of the products by some dealers and purchasing personnel, there have been errors in the selection of manual or automatic models. In order to completely solve this problem, the new product development department of Wenzhou Zhongguan Precision Electromechanical Manufacturing Co., Ltd. has developed this hand-automatic dual-purpose. Type products, whether it is manual or automatic, you can choose this type.

Installation and use:

Fourth, installation and use

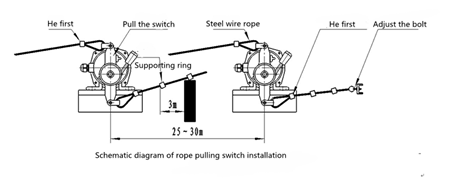

(1) The switch is mounted smoothly on the rack mount bracket.

(2) Attach the wire rope to the ends of the pull ring, each side of the rope does not exceed 40 meters

(It should be shortened to 25 meters when there is slope)

(3) The pulling action of the rope should be appropriate to ensure a reliable reset of the switch.

(4) The wire rope is placed along the parallel direction of the tape, and a ring is added every 10 meters.

(5) If you need to change the switch to manual, screw the threaded bolt at the front end of the manual reset device clockwise into the threaded interface of the rocker arm and tighten with a 14-opening wrench (tighten, do not use excessive force).