Tel:0577-21019000

E-mail:zograjd@163.com

Product manual:

|

Environmental Temperature |

-30°C~+60°C |

Relative Humidity |

Not greater than 85% |

|

Number of contacts |

1Normally open 1 normally closed (customizable) |

Contact Capacity |

24~380V AC/DC Current: 1:5A |

|

Action Angle |

30° |

Limited Angles |

60° |

|

Action |

10KG |

reliability |

>106 |

|

Protection level |

IP65 |

Reference Weight |

1.5KG |

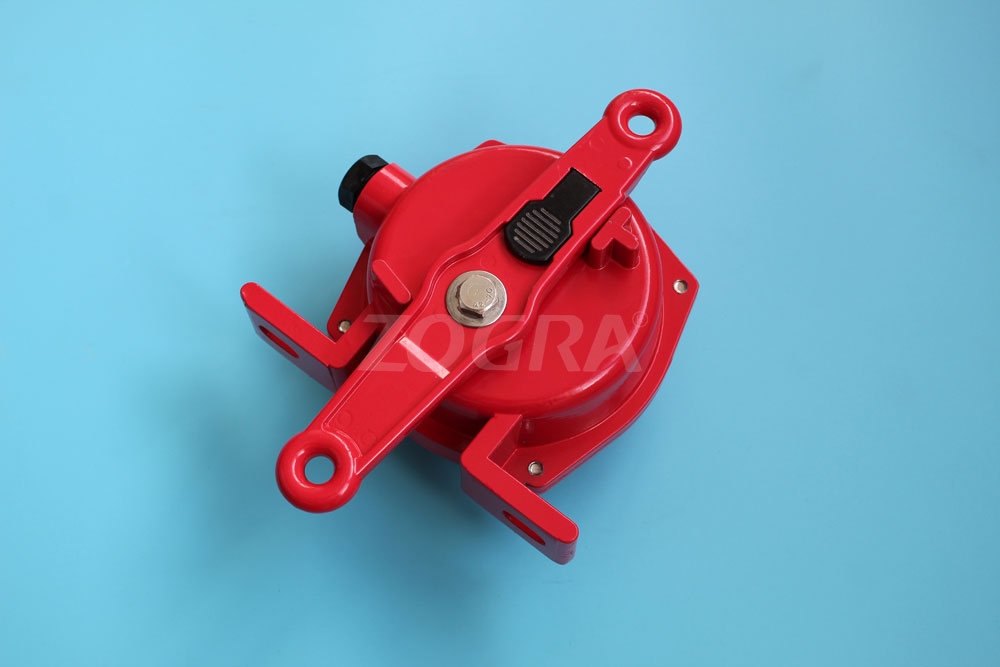

The two-way rope switch is widely used in factories and mines with belt conveyors such as steel, cement, power plants and mines. The product is installed on both sides of the belt conveyor and is a kind of protection switch for the emergency stop of the belt conveyor. Pull the wire rope at any point within the operating distance, cut off the running circuit to stop the whole line, and realize the protection of the tape machine and personal safety. When an emergency occurs at the belt transportation site, the wire rope attached to the lifting lug is used as a slider and a switch in the machine to send a shutdown signal.

This product has self-locking protection, can be reset after pressing the limit rod after accident elimination; long service life; good sealing performance, dustproof, shockproof, anti-corrosion, etc.; the casing is cast by cast aluminum, light weight and strong hardness.

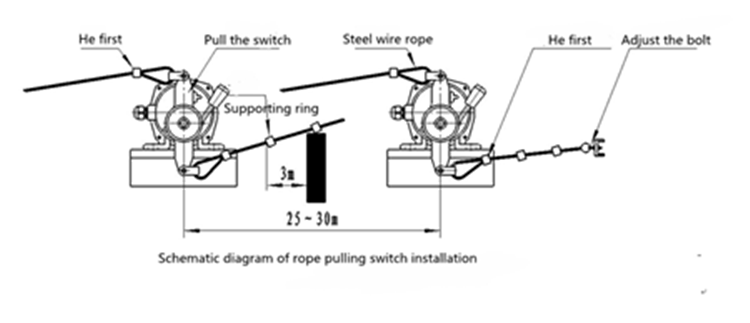

Installation and use:

1) The switch is mounted smoothly on the rack mounting bracket.

2) Attach the wire rope to the two ends of the pull ring, the length of each side rope should not exceed 40 meters (the length should be shortened to 25 meters when there is slope)

3) The pulling action of the rope should be appropriate to ensure a reliable reset of the switch.

4) The wire rope is placed along the parallel direction of the tape, and a ring is added every 10 meters.

The mounting bracket is not provided with the switch and needs to be purchased separately; the mounting bracket style, the number of switch points, can be customized according to user requirements