Tel:0577-21019000

E-mail:zograjd@163.com

|

Environmental Temperature |

-30°C~+75°C |

Relative Humidity |

Not greater than 85% |

|

Belt speed |

Applicable speeds up to 6.35 m/s |

Adjustment scope |

Action bar normal angle adjustment range is 22.5° |

|

Alarm Angle |

When the normal angle is 10 degrees |

Shutdown Angle |

The normal angle is 20 degrees |

|

Rated Speed |

Action Rod Bearing 5000 rpm |

reliability |

Greater than 106 |

|

Protection level |

IP65 |

Reference Weight |

3.5KG |

product manual:

The anti-bias switch is used for belt deviation detection and can be fixed on the top or bottom of the conveyor longitudinal beam. It is usually installed at the ends of the belt 0.3 to 2 meters away from the head or tail roller. After the belt runs off, the action arm is forced to deviate and the alarm micro switch is activated. If you continue to deviate from the stop contact and touch another set of contacts, the conveyor will stop mechanically.

Application range

●Conventional belt conveyor ●Underground ropeway support belt conveyor ●Wheel loading and unloading system

●Stacking and reclaiming conveyor ●Tilt and shuttle conveyor ●Crane excavator boom limit

● Skirt feeder conveyor ● Heavy duty limit switch

Special options

●Stainless steel cover screws ●Stainless steel action rod and stainless steel vertical roller

●Optional mounting bracket ●Can increase the number of switching points

Installation Notes:

1) Universal mounting design allows the anti-bias switch to be mounted freely on the top or bottom of the conveyor stringer

2) Sturdy cast aluminum housing, protection standard NEMA4, special environment optional special surface treatment

3) The integral cover is easy to connect, the switch adjustment is convenient and simple, and the cover can be removed without removing the action lever.

4) The rated speed of the action rod bearing is 5000 rpm, and the applicable belt speed can reach 6.35 m/s.

5) The adjustment angle of the action lever normal angle is 22.5°

6) When the normal angle is 10 degrees, the alarm contact will act. When the normal angle is 20 degrees, the stop contact will act.

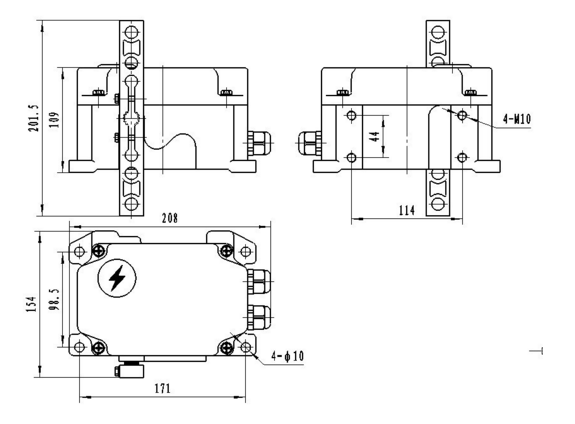

physical dimension:

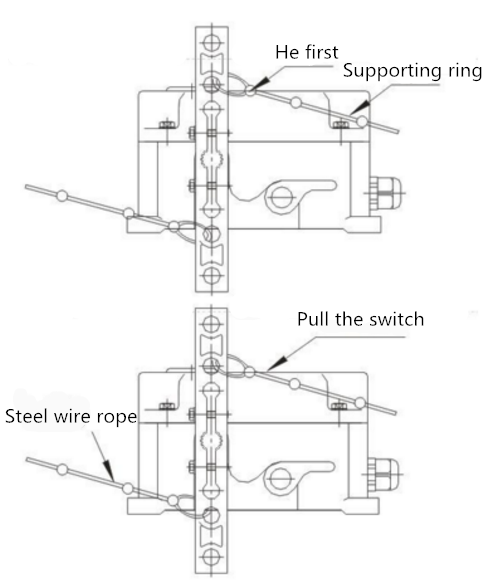

Installation and use:

1) The switch is balanced on the fixed bracket of the frame;

2) Attach the wire rope to the pull ring at both ends, and the rope on each side should not exceed 30M (when there is slope, it should be shortened);

3) The drawstring pressure should be appropriate to ensure reliable reset of the switch;

4) The drawstring is arranged along the parallel direction of the tape, and a ring is added every 10M;

5) The wire rope can be purchased according to the specifications required by the user.