Tel:0577-21019000

E-mail:zograjd@163.com

|

Environmental temperature |

-30°C~+60°C |

Relative Humidity |

Not greater than 85% |

|

Number of contacts |

2 groups of switches |

Contact Capacity |

380V AC 5A |

|

Action Angle |

12-30/10-45/25-35/15-45 etc. |

Extreme Angle |

70° |

|

Reset method |

Automatic reset |

Reliability |

>106 |

|

Protection level |

IP65 |

Reference Weight |

2KG |

Product Description:

The two-level deviation switch is mainly used for conveyor belt deviation detection to prevent the material from running out of the tape and causing material overflow. When the tape is deflected, the edge of the tape drives the stick to rotate and squeeze the stick to tilt it. If the tilting of the stick is greater than the first-level action angle, the switch will send out a set of signals for warning. If the stick is tilted more than the second-level action angle, the switch will send another set of signals for stopping. After the belt conveyor resumes normal operation, the stick automatically resets.

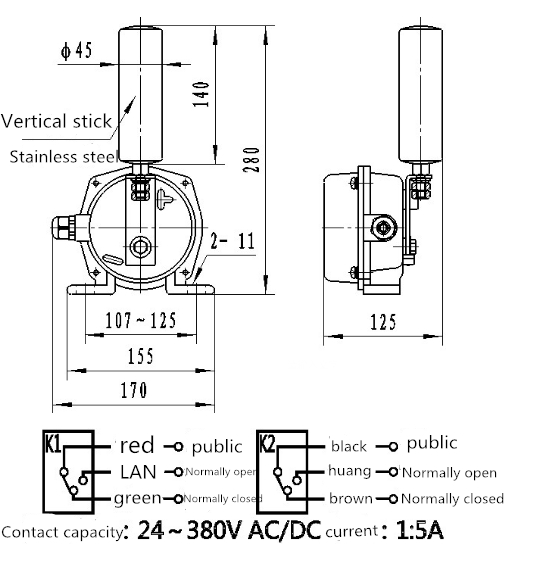

The two-level deviation switch has two micro-switches K1; K2, which can be connected to normally open or normally closed according to actual needs.

This product can replace a similar model:

HFKPT2-12-30

HFKPT2-10-45

HFKPT2-25-35

HFKPT2-15-45

Wholesale HFKPT2

(Adjust the action angle according to customer requirements)

Install and use

1) The switch is balanced on the rack mount and then soldered to the tape rack;

2) The axis of the stick is perpendicular to the surface of the tape, and the distance between the stick and the edge of the tape is 50mm-100mm;

3) The tape is located at 1/3 of the lower end of the stick;

4) A minimum of one pair of deviation switches is required for each 50m tape.

Dimensions: